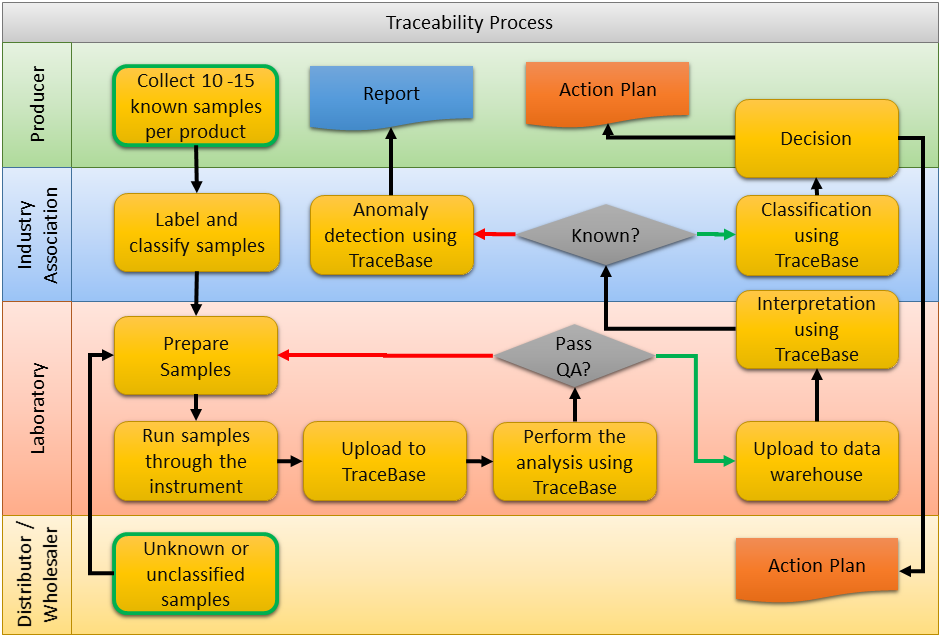

- The Producer collects between 10 and 15 samples of each product in a specific location.

- Then the producer sends the samples to the industry association for processing.

- The industry association representative will then label classify, and package the samples and send it to the lab.

- The Analyst at the Lab then prepares the samples according to a standard and place them as part of a batch in the auto sampler of the instrument.

- The Analyst then processes then batch through the ICP-MS and ICP-AES instruments. The instruments produces a file with a count per second value for every detectable element, around 64 of them for each sample.

- Next the analyst uploads the output from the instrument to TraceBase®.

- The analyst then performs a series of steps to remove interference, and calibrate the samples in order to produce the concentrations in parts per billion of all detected elements.

- Next the analyst performs a series of quality control steps and upload the data to the data warehouse section of the system.

- Once uploaded to the data warehouse the analyst or trained industry representative can start the interpretive stage of the process. This is done with the help of Artificial Intelligence software.

- If it is a known sample as part of a sample batch the industry representative will perform a series of classifications to detect any anomalies with the use of a neural network.

- If it is an unknown sample send to the lab for verification purposes the industry representative will first have to match the sample to a know location. If the industry representative are not able to match the sample they will need assistance from the analyst.

- Once the traceability process have been completed, the industry association can produce an appropriate action plan.